History: In 1974 HPT (High Performance Tube, Inc.) pioneered the manufacture of integral low-fin tubing in hard to work alloys such as titanium, stainless steels, and high nickel alloys. This innovation paved the way for new industrial applications of enhanced surface heat transfer. In 2013 the HPT Fin Tube production was moved to Morristown TN USA and integrated into our titanium and stainless welded tube facility. NEOTISS continues to expand upon the HPT Fin Tube product line and remains an industry leader in enhanced surface tubular products.

Applications: NEOTISS HPT Low-Fin Tubes are used in shell and tube type heat exchangers to improve energy efficiency in refining, petrochemical, LNG, power generation, refrigeration, heating and air conditioning plants world-wide.

Benefits: Increased surface area for heat transfer, smaller heat exchanger, less number of heat exchangers, reduced equipment and installation cost, debottlenecking existing heat exchangers, upgrading to corrosion resistant alloys without sacrificing heat transfer efficiency, and reduced fouling (in some cases).

|

|

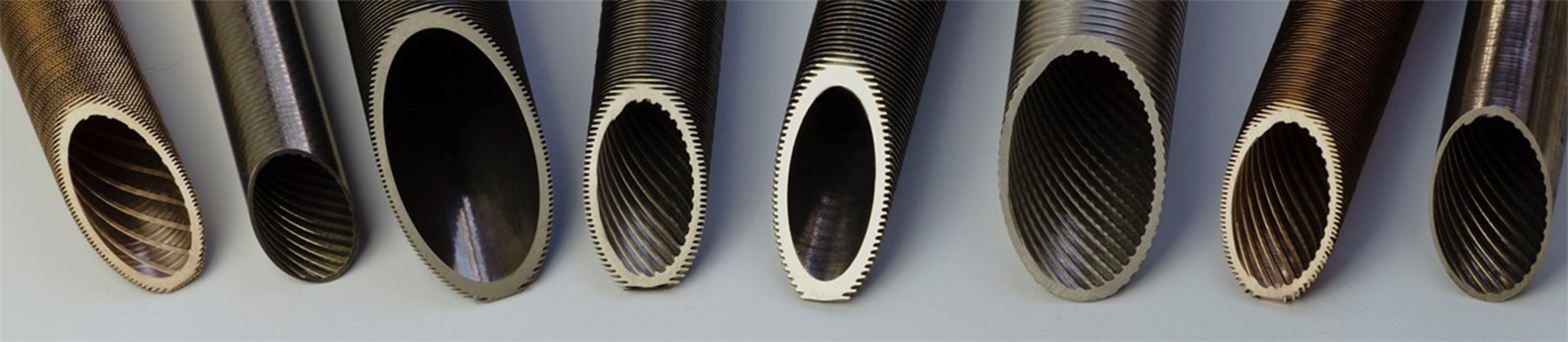

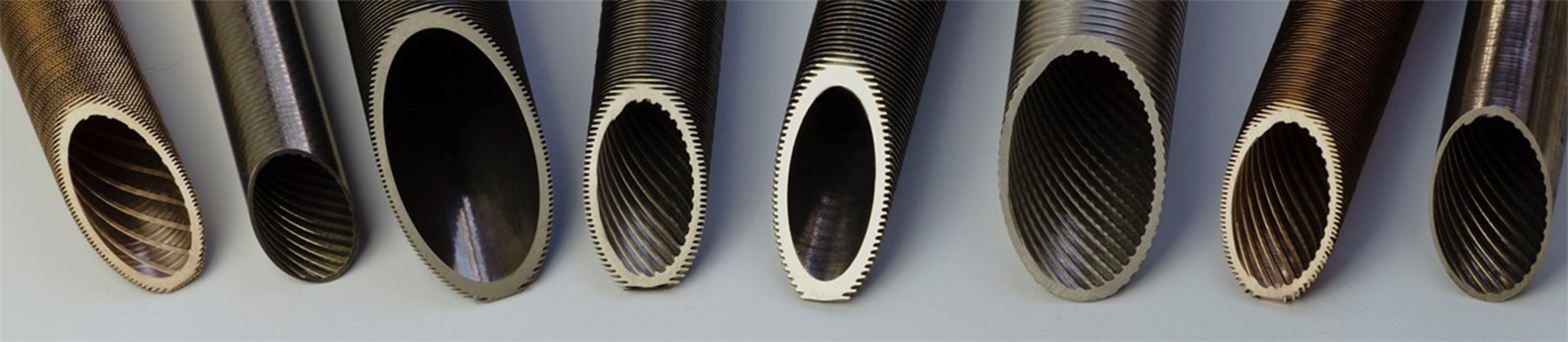

Type 1: 30 fins per inch / .032 fin height

Titanium and High Nickel Alloys

|

|

Type 2: 28 fins per Inch / .035 fin height

Stainless Steel and Duplex Steel

|

|

Type 3: 26 fins per inch / .049 fin height

Copper Alloys, Carbon Steel, and Ferritic Steel

|

|

Type 4: 36 fins per inch / .026 fin height

Titanium – light wall

|

|

Legacy 19 fins per inch / .055 fin height

Carbon Steel, Cu-Ni

|

|

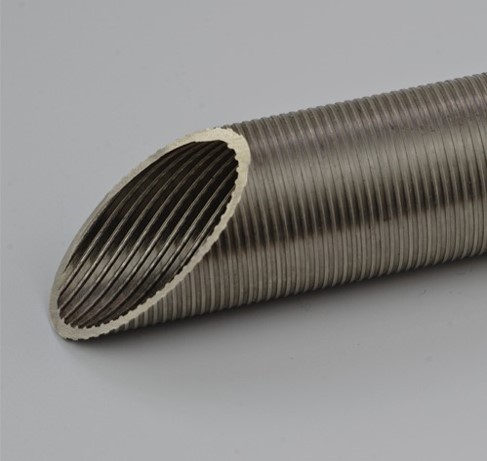

Low Fin OD / Smooth ID

- Provides 2.5 to 3 times greater external surface area compared to smooth tube.

- Ideal for shell side controlling heat exchanger applications

- Available in a wide range of materials and sizes (download individual data sheets or complete catalog)

|

|

|

Type 6: 36 fins per Inch OD / 20 Rib ID

Titanium

|

|

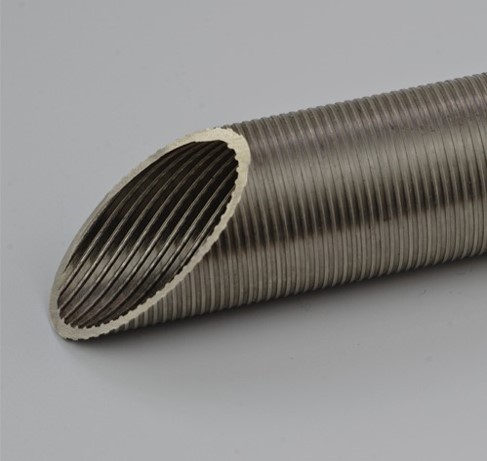

Type 7: 28 Fins per Inch OD / 20 Rib ID

Austenitic Stainless Steel

|

|

Type 8: 26 fins per inch OD / 20 Rib ID

Copper Alloys, Carbon Steel, and Ferritic Steel

|

|

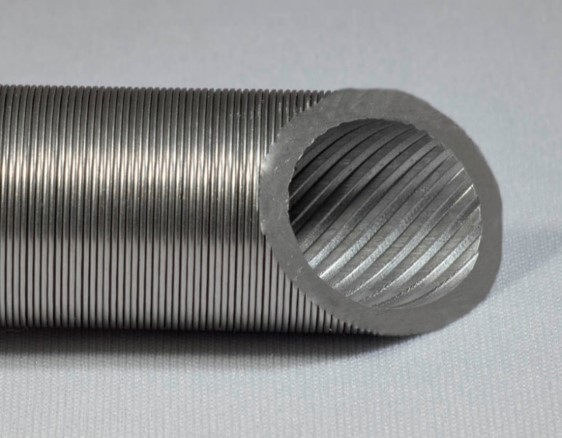

Low Fin OD with Internal Rib

- Combines 2.5 to 3 times greater external surface area with an enhanced ID surface

- Internal helical ridges create higher heat transfer through increased turbulent flow.

- Available in a wide range of materials and sizes (download individual data sheets or complete catalog)

|

|

|

Type 9: Wave Tube

Titanium, Stainless Steel

|

|

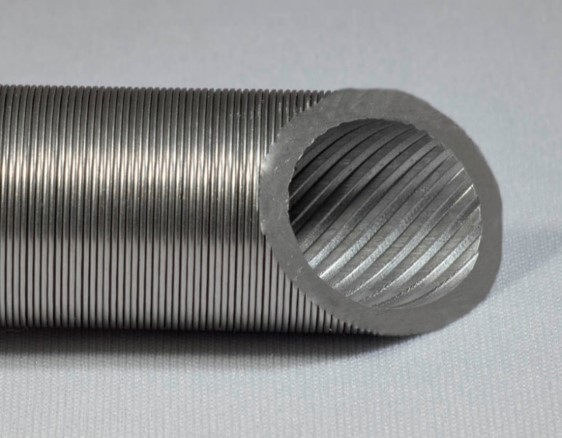

Ribbed OD and ID

- Recommended for ID controlling cases where traditional low-fin OD is not appropriate.

- Internal helical ridges create higher heat transfer through increased turbulent flow.

|

|

|

Type 10: Smooth OD / Microfin ID

Titanium, stainless Steel

|

|

Smooth OD with Microfin ID

- Recommended for ID controlling cases where traditional low-fin OD is not appropriate.

- Internal helical ridges create higher heat transfer through increased turbulent flow.

|

|

|

NEOTISS Thermo-C36

Cu, Cu-Ni

|

|

NEOTISS Thermo-C46

Cu, Cu-Ni

|

|

Engineered Fin OD with Microfin ID

- The Modified OD fin structure for improved refrigerant condensing shell side

- The Internal enhancement is available in low and high density options.

|

|

|

NEOTISS Thermo-B

Carbon Steel

|

|

Engineered Boiling Surface OD with Microfin ID

- Modified fin structure for nucleate boiling shell side at low temperature approaches

- Available with various internal fin geometries or smooth bore.

|

|

|

NEOTISS 3D FIN

Titanium, Cu-Ni, Carbon Steel

|

|

3D Fin OD with internal rib:

- Fin shape and spacing is optimized for high surface tension fluids.

- Available with internal rib or smooth bore

|