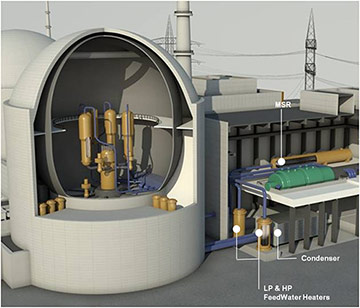

We supply welded tubes for heat exchangers in fossil power plants. Our high-performance welded tubes are used in Condensers, High-Pressure and Low-Pressure FeedWater Heaters.

©Vallourec

Condensers

The surface condenser is a key factor in plant performance. Its primary function is to condense the exhaust steam from the low-pressure turbine and return the feedwater to the steam generator or the boiler. The steam is condensed on the tube outside surface as the cooling water flows through the tube.

The cooling water can flow either from a closed- or an open-loop system which makes the condenser a critical component. Indeed, raw water ingress can contaminate the chemically controlled steam/water loop.

Products & Solutions

Condenser tubes material :

- Titanium Grade 2

- Stainless Steel (mainly 304, 304L, 316, 316L,317L, 2205, LDX2101)

- Super Stainless Steel (AL6XN®, 29-4C®, 254SMO®, 2507)

Condenser tubes design :

- Smooth or Helix

- Straight

LP & HP FeedWater Heaters

Application & Challenges

Low-Pressure and High-Pressure FeedWater Heaters extract steam from the low- and high- pressure turbines to heat the feedwater from the condenser and forward it to the primary loop of the boiler or the steam generator. The intelligent use of this energy source is critical for the overall efficiency of a power plant.

Products & Solutions

Low Pressure FeedWater Heater tubes :

- Material: Austenitic Stainless Steel (mainly 304, 304N, 304L, 316, 316L)

- Design: Smooth & Bent

High Pressure FeedWater Heater tubes :

- Material: Austenitic stainless steel (mainly 304, 304N)

- Design: Smooth & Bent

More than 500 fossil power plants delivered

More than 800 fossil condensers delivered

More than 800 fossil LP & HP FWH delivered