Titanium is the most efficient material for many applications requesting both corrosion resistance and high mechanical properties. Titanium may from first analysis appear as one exotic and expensive solution compared to copper nickel alloys but its competitiveness can be demonstrated through design optimization (reduced thickness and weight) and longer life time expectation (reduced maintenance costs).

Late 2010, the Ras Al Khair plant in Saudi Arabia was the first huge desalination project designed using titanium tubes exclusively. This challenging decision allowed DHIC to offer one very competitive solution to market.

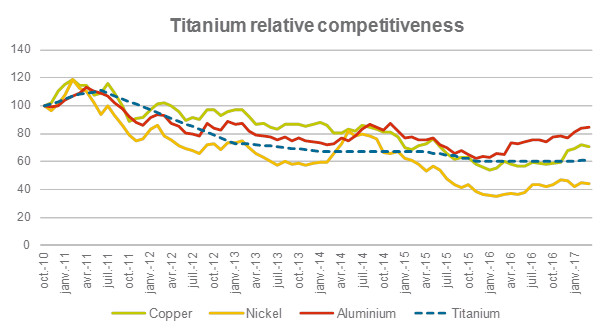

Since then, as shown on below chart gathering official raw material indicators, titanium followed the trend of other materials and thus has globally kept its competitive advantage.

For all materials including titanium, the trend is difficult to predict over medium to long term. Main concern with titanium is that the existing indicators are less reliable compared to other metals as Nickel or Copper. We expect this to evolve within next future with the improvement of the titanium indicators thanks to a wider and more standard use for industrial applications. Such change will certainly help the titanium to become a real standard material on the side of Copper or Aluminum.